NTD-165 南常3D定量切片機特點:

迎接定量切片的新時代!

可用少人數達到大量處理的高速定量加工系統登場!

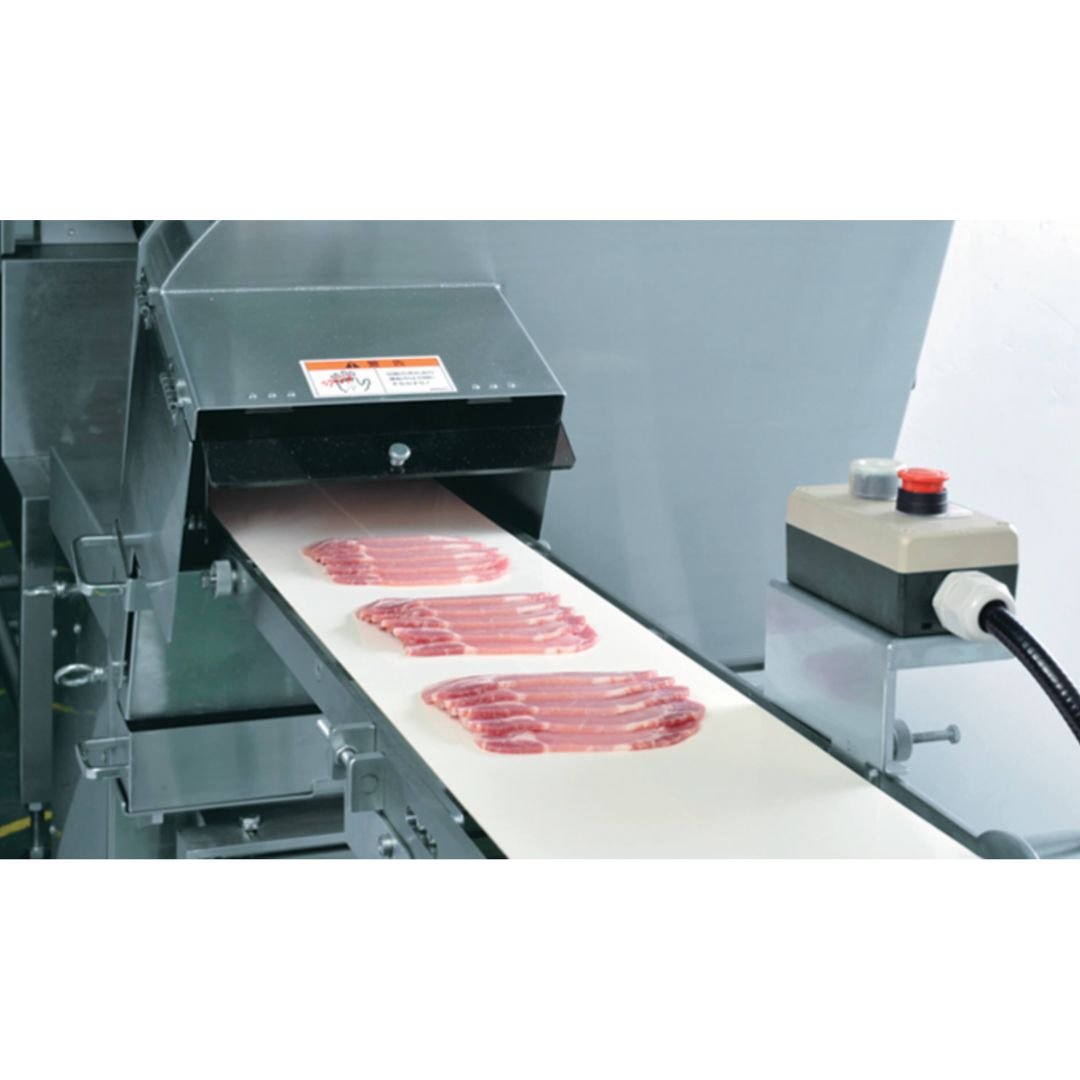

高速定量切片

-8℃~-2℃*根據肉的厚度、肉質和形狀略有不同。 定量切片、可隨意設定並在傳送帶上排列出所希望的分組切片的每組片數和間隔等。

因采用非接觸式測定方法而保證了商品的價值提升

通過位置可變的傳感裝置讀取和測量肉材的形狀、不與肉直接接觸、既保證了產品的衛生、又不會發生商品的變形。 不與商品直接接觸、故不會對商品產生任何的損毀。

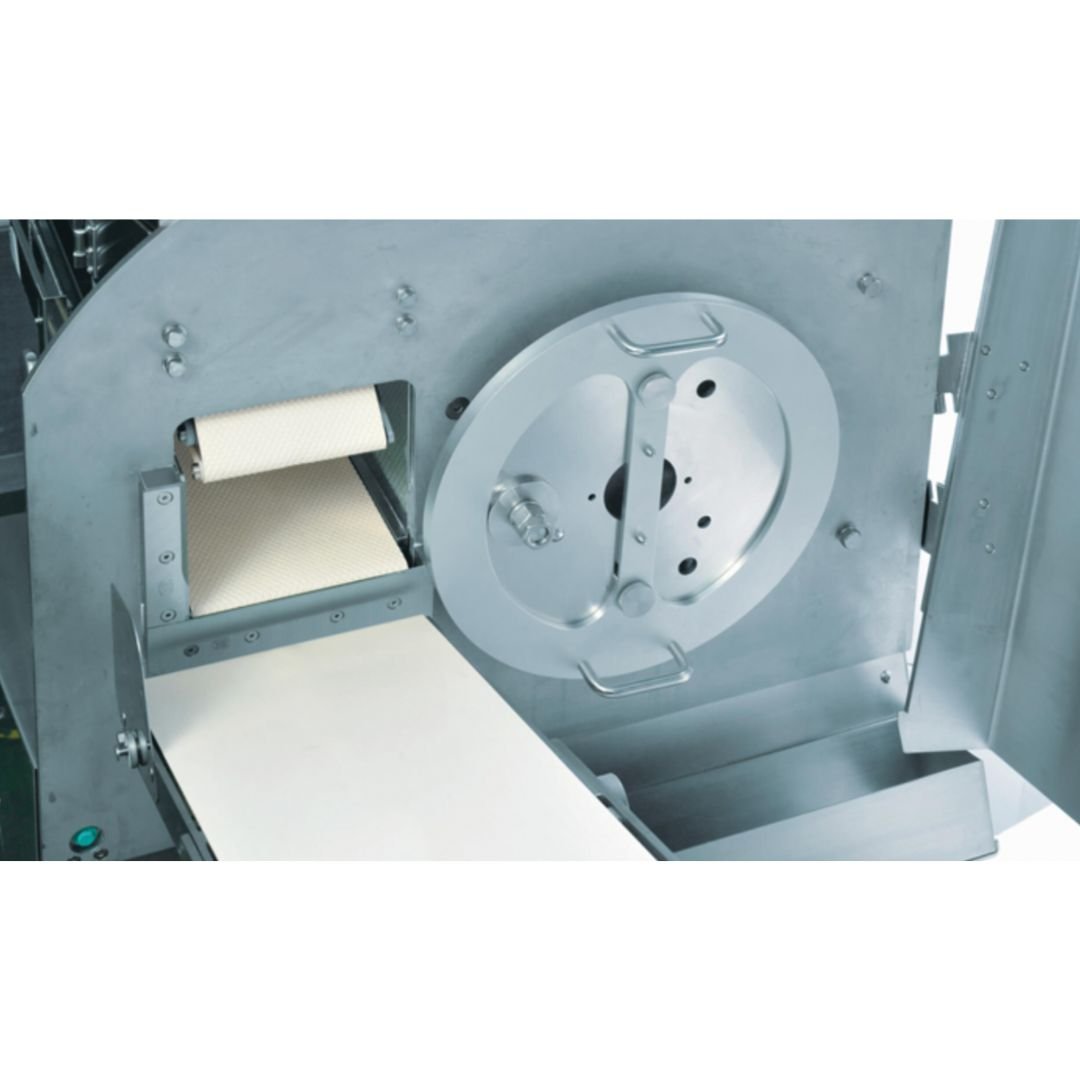

采用圓刀進行切片、可時刻保證刀刃的鋒利

南常獨特的圓刀偏芯技術決定了刀片的超群鋒利。由於配備了專用的研磨裝置、可自行進行半自動化的研磨、從而可以使刀具的鋒利程度得以保證。通過變更圓刀的固定位置、可以使圓刀的使用壽命延長至普通圓刀的3倍。

可以簡單操作的液晶觸摸幕

采用了易看易操作的彩色觸摸屏。所有設定均非常簡便、任何人均可簡單的進行定量加工作業。

最高可達到250片/分的切片速度

還可以作為定厚切片、從超薄切片到較厚肉片、可加工較大範圍的不同厚度的切片作業。

NTD-165 3D Fixed Weight Slicer Features :

The new era of fixed weight slicer.

A high-speed fixed weight slicing system that allows a small number of people to process a large amount of material is now available!

HIGH SPEED FIXED WEIGHT SLICE

The shape of the meat rod is read by the 3D measuring instrument before slicing, eliminating the need for weight feedback and enabling fast fixed weight processing.

The number of consecutive slices, intermittent slices, and spacing of slices can be freely arranged on the conveyor.

IMPROVING PRODUCT VALUE WITH NON-CONTACT MEASUREMENT

The shape is read by the displacement sensor without contact, which is hygienic and will not deform the product. The product value is not compromised because the product is not stressed.

ROUNDED BLADE FOR STABLE SHARP CUTTING

Our unique round-blade eccentricity technology achieves outstanding sharpness. Semi-automatic grinding is performed by a special grinding device to maintain stable sharpness. The position of the blade can be changed which makes it last 3 times longer than the normal round blade.

LCD TOUCH PANEL FOR EASY OPERATION

Adopts a color touch panel that is easy to view and operate. There are no difficult settings, and anyone can easily perform fixed weight slicing.

MAX.250 PCS/MIN. HIGH SPEED REGULAR SLICE

It can be used to slice a wide range of foods in fixed thickness, from grilled pork loin to grilled meat products.